Ceramic and Fibreglass Insulation

Anchoring Systems

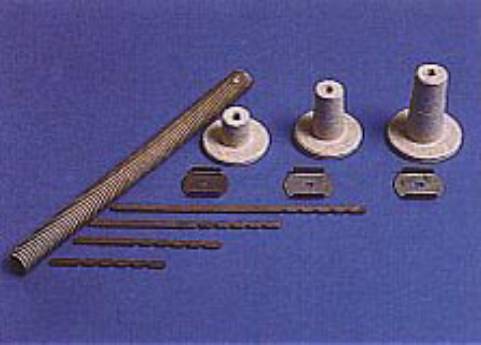

Hardware and Anchors

These have been developed to provide maximum, long term lining retention for an assortment of fiberwall lining systems including layered blanket and board. The most widely used metal anchor is the Insultwist Stud and Washer. The stud is a rectangular cross-section bar with notches in the sides which bring the cross-section back to square. The retaining clip is a washer with a rectangular slot in the centre and fits over the stud. Parallel to the slot, two sides of the washer have been flanged 90 degrees to facilitate placement.

For furnaces operating at temperatures above the maximum recommended use temperature of alloy studs the Cuplock Anchor is used in conjunction with the Insultwist Stud. The ceramic Cuplock replaces the metal washer.

Modules

These are prefabricated modular units comprising of a single roll of needled blanket, folded to a specified thickness and compression. Installation is simple, fast and efficient, with a high degree of reliability and integrity.

Ceramic Blanket

Insulating blankets are used in the appliance, ceramic, chemical processing, glass and metals industries in a great variety of insulating and fire protection applications. These products are lightweight and flexible consisting of fibres interlocked to form a strong, resilient material. They are extremely efficient insulators, with low heat storage capacity and complete resistance to thermal shock.

A strong, lightweight, double needled blanket is rated to 1260°C. Blanket with a higher alumina content is rated for use to 1400°C providing excellent handling qualities in both hot and cold states. We also provide a zircon blanket which is suitable for continuous use at elevated temperatures. This blanket is made from high purity raw materials to substantially reduce shrinkage.

Ceramic Board

Insulating Board has low permeability, low thermal conductivity and high temperature stability. These boards have excellent resistance to thermal shock, good strength and rigidity and are easy to fabricate.

This insulation is a low density product with uniform density across its entire thickness and ideal for thermal areas subject to vibration or mechanical stress. Temperature ratings vary between 1260°C and 1427°C.

High quality, versatile papers have exceptional strength and flexibility, and superior insulating and handling characteristics.

These ceramic fibre based products can be easily trimmed, shaped and fitted to cover, wrap or line irregular shapes using ordinary hand scissors. Rated to 1250°C.

Bulk Fibre insulation is a soft, fluffy material, supplied in bags at a packed density of 96 – 192 kg/m³. The fibre provides superior resilience and ease of compression in insulating and general maintenance applications. Bulk Fibre is used as a high temperature fill or packing material in a variety of high temperature applications. Melting point is 1790°C.

These products have excellent resistance to thermal shock, corrosive attack and breakdown due to mechanical vibration and stress. A blend of long-staple fibres and organic carrier fibres, these textiles are an excellent choice where a flexible, strong temperature resistant product is required. All rated to 1260°C.

Fibersil Cloth – Wire-reinforced cloth, assures high performance and durability in applications to 980°C.

Rope – A resilient refractory possessing thermal properties and chemical stability. Used for gasketing, packing and sealing applications.

Braid – Used in applications which require high density as well as resistance to compression and mechanical abuse.

Wet mix products have high temperature stability, low thermal conductivity, low heat storage and good strength. They resist abrasion and erosion and have excellent resistance to thermal shock and chemical attack.

Rigidiser: Rigidiser is an organic liquid compound which is used as a surface treating agent to increase hardness and erosion resistance. Rigidiser will improve flame erosion resistance and reduce permeability to gases. Rated to 870°C.

Moldable: This ceramic fibre moldable mix is characterised by excellent wet adhesion to steel refractories and other ceramic fibre materials. Moldable is a sticky, putty-like, ready-to-use product with almost zero drying shrinkage. Rated to 1260°C.

Topcoat: Topcoat is a mixture of high temperature mullite refractory reinforced with Fibremax fibres designed as a coating for ceramic fibre. This provides additional resistance to slag, alkali attack and velocity attack when applied over ceramic fibre.

QF Coating Cement:These coating cements are applied to the surface of ceramic fibre blankets and papers to increase their strength and resistance to hot gas erosion. They are also used as high temperature adhesives for ceramic fibre products. Supplied in paste and paint consistencies, these coating cements can be trowelled, brushed or sprayed. Rated to 1260°C.

Pumpable XJ: When this pumpable mastic is subjected to temperatures above 250°C, it becomes a flexible resilient insulation with a semi rigid outer crust. Rated to 1260°C.

Fyre Putty: Fyre Putty is a fibre-based fire stop material which is easy to install and is thermal shock resistant. Fyre Putty provides an effective barrier for smoke, moisture and gas as well as fire and heat. Rated to 1260°C.

Wet Pac: Made from high strength ceramic fibre blanket and inorganic bonding agents, resulting in a flexible moist insulation that dries to a hard rigid structure. WetPac is deal for insulation of complex shapes and for service under hot gas velocities. Rated to 1260°C.

Variform: is a casting material that is applied to areas such as furnace access-doors, tube sheets and behind refractories in aluminium transfer ladles, ladle covers and launders.